Regain SPL Solution

The Regain Spent Potlining (SPL) Solution is an “Industrial Ecology” approach to transforming a hazardous waste into valuable by-products.

The Regain SPL Solution provides the process technology to detoxify and refine the SPL along with product off-take markets to take care of the SPL with no residual material. This approach:

- is a practical example of the circular economy concept through return of materials derived from SPL to the productive economy with both economic and environmental gains;

- is positioned higher in the waste hierarchy than other options for dealing with SPL; and

- represents a best available technique on a worldwide benchmark.

Using industrial ecology as a framework, Regain applies knowledge of how other industries can gain the best value from chemicals and minerals in aluminium smelter waste materials. Regain proprietary technology is used to detoxify and refine SPL and then to manufacture high quality products.

All of the Spent Potlining is transformed into safe products with genuine value in energy intensive industries such as cement manufacture. There is no residue from the Regain solution, which is a typical concern with other processing methods.

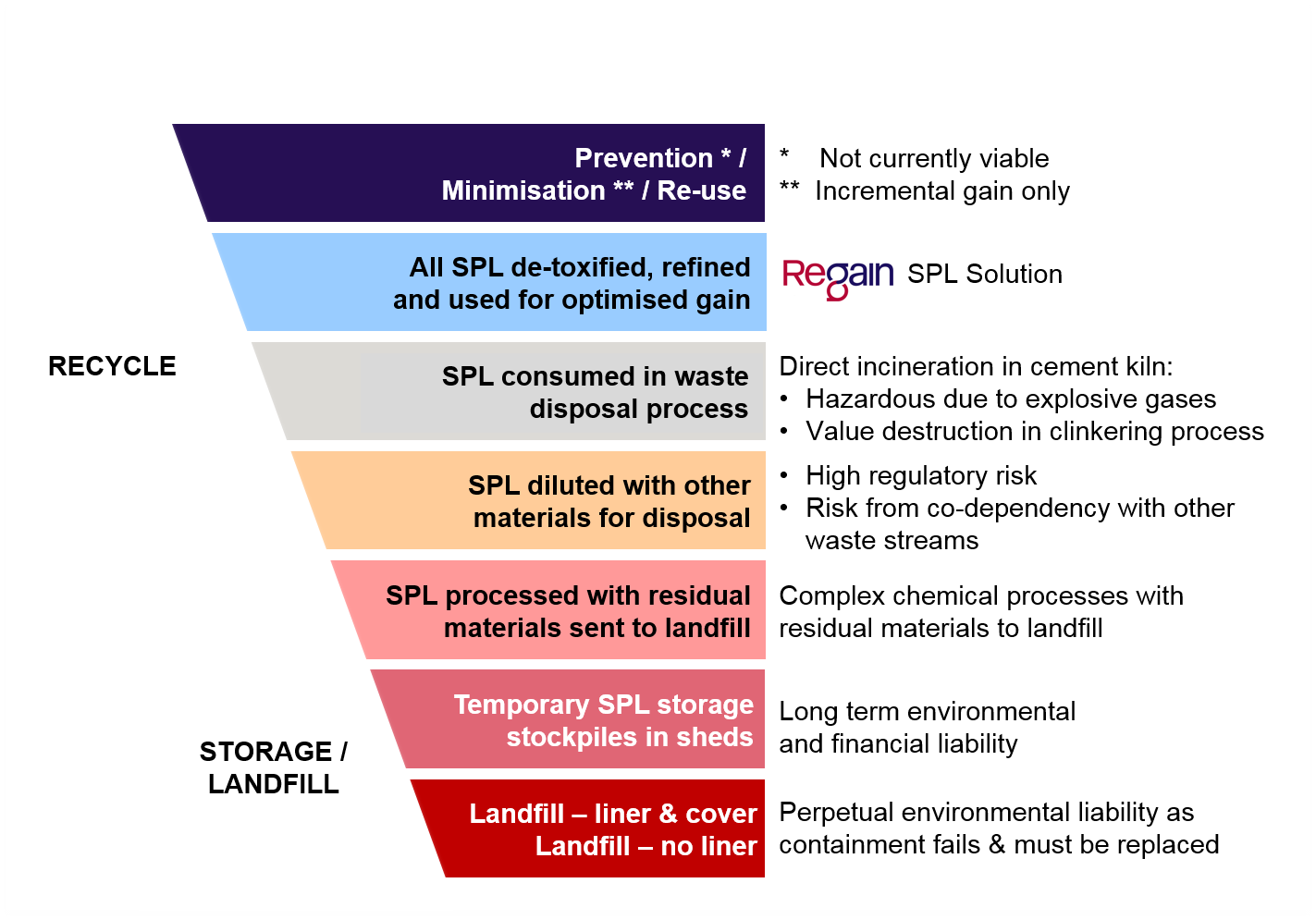

Best position on the waste hierarchy

The Regain SPL Solution delivers the highest practical outcome according to the waste management hierarchy.

Mature and proven solution with assured product markets

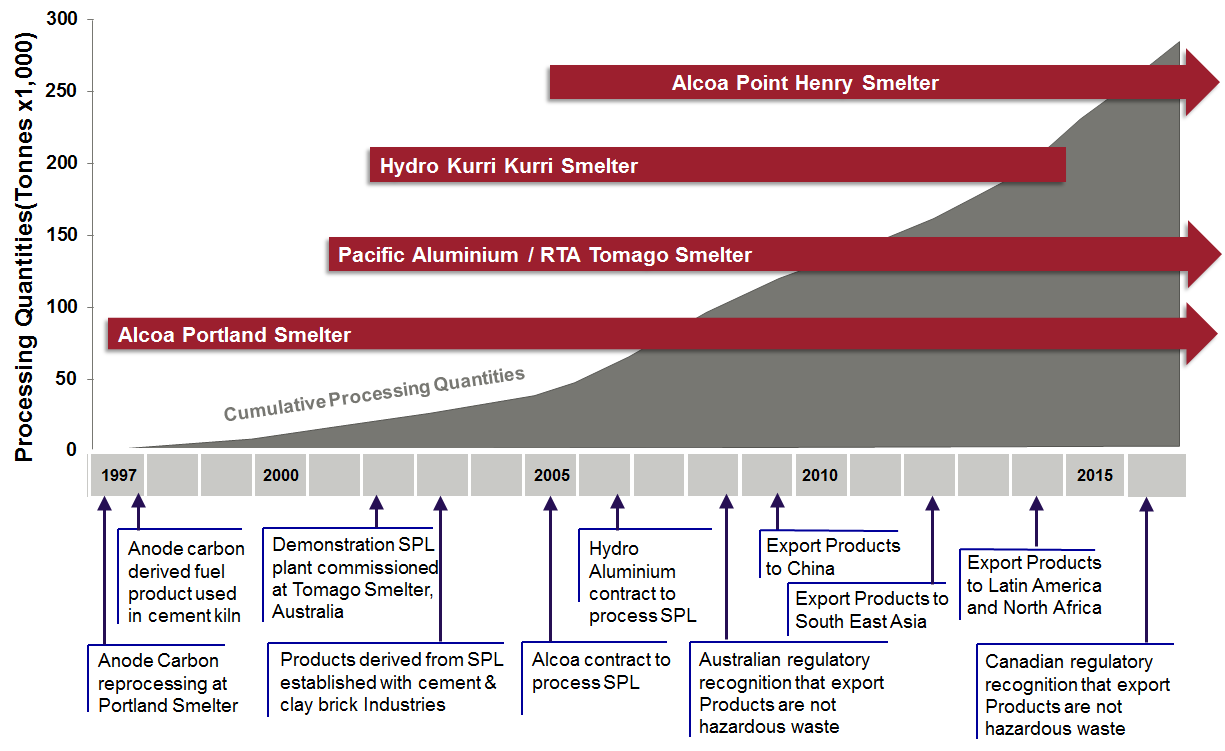

The Regain Regain SPL Solution is a mature approach proven with more than 300,000 tonnes of cyanide and fluoride contaminated waste diverted from the waste stream including more than 200,000 tonnes of SPL. It represents a viable techno-commercial solution to what has been an intractable problem for the primary aluminium smelting industry. Progressive cost reductions have been realised as benefits accruing from the technology learning curve, continuous improvement, economies of scale and revenues from the sale of refined products.

The costs to a smelter of transforming SPL using the Regain approach are now less than the typical liabilities associated with SPL in landfill due to the long term contaminating lifespan of SPL and the ongoing landfill remediation requirements.

Industrial Ecosystem for SPL

The SPL solution is based on a multi-party system, an "industrial ecosystem", comprising:

- Participating primary aluminium smelters

- SPL process plants provided to the smelters as part of the solution

- Manufacture, marketing and distribution of products derived from SPL that are valuable in energy intensive processes such as cement manufacture

- Cement manufacturers

- Enabling structure that integrates:

- technology to detoxify SPL

- technology to use the products in cement manufacture

- regulatory approvals for technology and products

- trading of manufactured products

- optimised marketing and logistics of products

- access to research and a body of knowledge to support use of the products

Read more about Regain's Safe, Sustainable SPL Solution:

Top