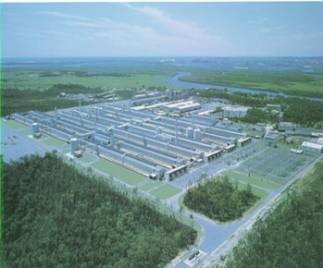

Neil Roser - Tomago Aluminium

"Look we can’t keep building sheds, it doesn’t make sense"

Like other aluminium producers in Australia, Tomago, one of the country’s biggest, has had to face the issue of what to do with spent pot liner. Neil Roser, environmental services team leader, explains that when Regain offered a ‘cradle to cradle’ solution, it ticked all the right boxes.

Located just outside of Newcastle, NSW, when Tomago was denied permission to dispose of spent pot liner to nearby landfill, they had to look for other options.

"For a while we basically built sheds to store the material,” Neil says. “We had a storage capacity of 34,000 tonnes.”

"For a while we basically built sheds to store the material,” Neil says. “We had a storage capacity of 34,000 tonnes.”

But even that was a stop gap measure.

“A lot of the smelters kept building sheds and building sheds,” he says. “We made a decision here to say 'look we can't keep building sheds, it doesn't make sense’.”

After a period of sending SPL to Europe for treatment and disposal on a campaign basis (8000 tonnes of material per shipment), they were committed to finding a local solution.

“We investigated concept plants ourselves too, however developing the market for the end product was a challenge,” he says. “We also had a lot of people come to the door and say 'yes we can treat it, yada yada yada’.”

There were a few treatment plants around Australia which according to Neil "had mixed success" but the question remained, "What do you do with this material after you treat it?"

Enter Regain which offered an expertise that was unique to the market.

"Regain came into the picture and what they brought to us was mineral experience,” he says. “So they had different knowledge base and different context to what we did in Aluminium."

Tomago was also attracted to Regain’s Industrial Ecology model of transforming waste into a valuable resource for another industry.

“What we like about Regain is the ‘cradle to cradle’ type scenario,” he says, referring to the re-use of SPL in the cement industry.

“If we give them a tonne of spent pot liner, they can say 'well that can go into the cement kiln after it is treated and handled correctly', so from the time we hand it to them…to the end use, it’s getting absorbed in the process,” he says. “It's so much sweeter when you can basically write off that liability you've inherited through aluminium making."

It’s safe to say that Regain has the approval of Neil’s environmental services department.

Broader environmental concerns within today’s society also play into Regain’s hands, according to Neil.

"As the world becomes more carbon conscious it's better not to be wasting fuel,” he says. "If the spent pot liner can be treated and go into cement kiln, then we are saving on energy that makes sense.”

Neil says that Regain’s Industrial Ecology model is ideally suited to today’s business drivers for cost-savings.

"If you asked a company what the value of that was in the 80s, probably not, but as prices of electricity and fuels go up, that value is there,” he says. “If Regain can present that to their (clients), without them having to do too much work, that's the advantage.”

Top